The Junkers Ju 87 Stuka Part 2

Development

Origins: Early design

The Ju 87's designer, Hermann Pohlmann, held the opinion that dive-bomber design needed to be simple and robust. This led to many technical innovations, such as the retractable undercarriage being discarded in favour of one of the Stuka's distinctive features, its fixed and "spatted" undercarriage.

Pohlmann continued to carry on developing and adding to his ideas and those of Karl Plauth (Plauth was killed in a flying accident in November 1927), and produced the Ju A 48 which underwent testing on 29 September 1928. The military version of the Ju A 48 was designated the Ju K 47.

Ernst Udet; the greatest proponent of the dive-bomber and the Ju 87 (Photo 1928)

After Hitler came to power, the design was given priority. Despite initial competition from the Henschel Hs 123, the Reichsluftfahrtministerium (RLM) - Aviation Ministry - turned to the designs of Pohlmann and Plauth. During the trials with the K 47 in 1932, the double vertical stabilisers were introduced to give the rear gunner a better field of fire. The main, and what was to become the distinctive, feature of the Ju 87 was its double-spar inverted gull wings. After Plauth's death, Pohlmann continued the development of the Junkers dive bomber. The Ju A 48 registration D-ITOR, was originally fitted with a BMW 132 engine, producing some 450 kW (600 hp). The machine was also fitted with dive brakes for dive testing. The aircraft was given a good evaluation and "exhibited very good flying characteristics"

Ernst Udet took an immediate liking to the concept of dive-bombing after flying the Curtiss Hawk II.

He invited Luftwaffe OC Walther Wever and Robert Ritter von Greim to him perform a trial flight in May 1934 at the Jüterbog artillery range, but it raised doubts about the capability of the dive bomber. Udet began his dive at 1,000 m (3,300 ft) and released his 1 kg (2.2 lb) bombs at 100 m (330 ft), barely recovering and pulling out of the dive. Wever, and the Secretary of State for Aviation, Erhard Milch, feared that such high-level nerves and skill could not be expected of "average pilots" in the Luftwaffe. Nevertheless, development continued at Junkers. Udet's "growing love affair" with the dive bomber pushed it to the forefront of German aviation development. He even went so far as to advocate that all medium bombers have dive-bombing capabilities.

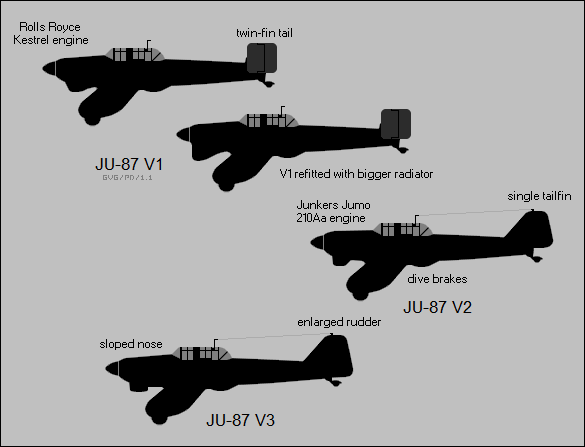

Ju 87 evolution

The design of the Ju 87 had begun in 1933 as part of the Sturzbomber-Programm. The Ju 87 was to be powered by the British Rolls-Royce Kestrel engine. Ten engines were ordered by Junkers in 19 April 1934 The first Ju 87 prototype was built by AB Flygindustri (sv) in Sweden and secretly brought to Germany in late 1934. It was to have been completed in April 1935, but, due to inadequate strength of the airframe, construction was not completed until October 1935. However, the mostly complete Ju 87 V1 W.Nr.c 4921 (less non-essential parts) took off for its maiden flight on 17 September 1935. The aircraft originally did not carry any registration, but later was given the registration D-UBYR. The flight report, by Hauptmann Willy Neuenhofen, stated the only problem was with the small radiator, which caused the power plant to overheat.

The Ju 87 V1, powered by a Rolls-Royce Kestrel V12 cylinder liquid-cooled engine, and with a twin-tail, crashed on 24 January 1936 at Kleutsch near Dresden, killing Junkers' chief test pilot, Neuenhofen, and his engineer, Kreft. The square twin fins and rudders proved too weak; they collapsed and the aircraft crashed after it entered an inverted spin during the testing of the terminal dynamic pressure in a dive.The crash prompted a change to a single vertical stabiliser tail design. To withstand strong forces during a dive, heavy plating was fitted, along with brackets riveted to the frame and longeron, to the fuselage. Other early additions included the installation of hydraulic dive brakes that were fitted under the leading edge and could rotate 90°.

The RLM was still not interested in the Ju 87 and was not impressed that it relied on a British engine. In late 1935, Junkers suggested fitting a DB 600 in-line engine, with the final variant to be equipped with the Jumo 210. This was accepted by the RLM as an interim solution. The reworking of the design began on 1 January 1936. The test flight could not be carried out for over two months due to a lack of adequate aircraft. The 24 January crash had already destroyed one machine.

The second prototype was also beset by design problems. It had its twin stabilizers removed and a single tail fin installed due to fears over stability. Due to a shortage of power plants, instead of a DB 600, a BMW "Hornet" engine was fitted. All these delays set back testing until 25 February 1936.[12] By March 1936, the second prototype, the V2, was finally fitted with the Jumo 210Aa power plant, which a year later was replaced by a Jumo 210 G (W.Nr. 19310). Although the testing went well, and the pilot, Flight Captain Hesselbach, praised its performance, Wolfram von Richthofen told the Junkers representative and Construction Office chief engineer Ernst Zindel that the Ju 87 stood little chance of becoming the Luftwaffe's main dive bomber, as it was underpowered in his opinion. On 9 June 1936, the RLM ordered cessation of development in favour of the Heinkel He 118, a rival design. Udet cancelled the order the next day, and development continued.

Heinkel's He 118, the main competitor to the Stuka

On 27 July 1936, Udet crashed the He 118 prototype, He 118 V1 D-UKYM. That same day, Charles Lindbergh was visiting Ernst Heinkel, so Heinkel could only communicate with Udet by telephone. According to this version of the story, Heinkel warned Udet about the propeller's fragility. Udet failed to consider this, so in a dive, the engine oversped and the propeller broke away. Immediately after this incident, Udet announced the Stuka the winner of the development contest.

Honing the design

Despite being chosen, the design was still lacking and drew frequent criticism from Wolfram von Richthofen. Testing of the V4 prototype (A Ju 87 A-0) in early 1937 revealed several problems. The Ju 87 could take off in just 250 m (820 ft) and climb to 1,875 m (6,152 ft) in just eight minutes with a 250 kg (550 lb) bomb load, and its cruising speed was 250 km/h (160 mph). However, Richthofen pushed for a more powerful engine. According to the test pilots, the Heinkel He 50 had a better acceleration rate, and could climb away from the target area much more quickly, avoiding enemy ground and air defences. Richthofen stated that any maximum speed below 350 km/h (220 mph) was unacceptable for those reasons. Pilots also complained that navigation and power plant instruments were mixed together, and were not easy to read, especially in combat. Despite this, pilots praised the aircraft's handling qualities and strong air-frame.

These problems were to be resolved by installing the Daimler-Benz DB 600 engine, but delays in development forced the installation of the Jumo 210 Da in-line engine. Flight testing began on 14 August 1936. Subsequent testing and progress fell short of Richthofen's hopes, although the machine's speed was increased to 280 km/h (170 mph) at ground level and 290 km/h (180 mph) at 1,250 m (4,100 ft), while maintaining its good handling ability.

The Ju 87 was a single-engined all-metal cantilever monoplane. It had a fixed undercarriage and could carry a two person crew. The main construction material was duralumin, and the external coverings were made of Duralumin sheeting. Parts that were required to be of strong construction, such as the wing flaps, were made of Pantal and its components made of Elektron. Bolts and parts that were required to take heavy stress were made of steel.

The Ju 87 was fitted with detachable hatches and removable coverings to aid and ease maintenance and overhaul. The designers avoided welding parts wherever possible, preferring moulded and cast parts instead. Large airframe segments were interchangeable as a complete unit, which increased speed of repair.

The airframe was also subdivided into sections to allow transport by road or rail. The wings were of standard Junkers double-wing construction. This gave the Ju 87 considerable advantage on take-off; even at a shallow angle, large lift forces were created through the aerofoil, reducing take-off and landing runs.

In accordance with the Aircraft Certification Center for "Stress Group 5", the Ju 87 had reached the acceptable structural strength requirements for a dive bomber. It was able to withstand diving speeds of 600 km/h (370 mph) and a maximum level speed of 340 km/h (210 mph) near ground level, and a flying weight of 4,300 kg (9,500 lb). Performance in the diving attack was enhanced by the introduction of dive brakes under each wing, which allowed the Ju 87 to maintain a constant speed and allow the pilot to steady his aim. It also prevented the crew from suffering extreme g forces and high acceleration during "pull-out" from the dive.

The fuselage had an oval cross-section and housed a water-cooled inverted-V V-12 engine. The cockpit was protected from the engine by a firewall ahead of the wing center section where the fuel tanks were located. At the rear of the cockpit, the bulkhead was covered by a canvas cover which could be breached by the crew in an emergency, enabling them to escape into the main fuselage. The canopy was split into two sections and joined by a strong welded steel frame. The canopy itself was made of Plexiglas and each compartment had its own "sliding hood" for the two crew members.

The engine was mounted on two main support frames that were supported by two tubular struts. The frame structure was triangulated and emanated from the fuselage. The main frames were bolted onto the power plant in its top quarter. In turn, the frames were attached to the firewall by universal joints. The firewall itself was constructed from asbestos mesh with dural sheets on both sides. All conduits passing through had to be arranged so that no harmful gases could penetrate the cockpit.

The fuel system comprised two fuel tanks between the main (forward) and rear spars of the (inner) an-hedral wing section of the port and starboard wings, each with 240 L The tanks also had a predetermined limit which, if passed, would warn the pilot via a red warning light in the cockpit. The fuel was injected via a pump from the tanks to the power plant. Should this shut down, it could be pumped manually using a hand-pump on the fuel cock armature.

The power plant was cooled by a 10 L (3 US gal) ring-shaped aluminium water container situated between the propeller and engine. A further container of 20 L (5 US gal) was positioned under the engine. The control surfaces operated in much the same way as other aircraft, with the exception of the innovative automatic pull-out system. Releasing the bomb initiated the pull-out, or automatic recovery and climb, upon the deflection of the dive brakes. The pilot could override the system by exerting significant force on the control column and taking manual control.

The wing was the most unusual feature. It consisted of a single center section and two outer sections installed using four universal joints. The center section had a large negative dihedral (anhedral) and the outer surfaces a positive dihedral. This created the inverted gull, or "cranked", wing pattern along the Ju 87's leading edge. The shape of the wing improved the pilot's ground visibility and also allowed a shorter undercarriage height. The center section protruded by only 3 m (9 ft 10 in) on either side.

The offensive armament was two 7.92 mm (.312 in) MG 17 machine guns fitted one in each wing outboard of undercarriage, operated by a mechanical pneumatic system from the pilot's control column. The rear gunner/radio operator operated one 7.92 mm (.312 in) MG 15 machine gun for defensive purposes.

The engine and propeller had automatic controls, and an auto-trimmer made the aircraft tail-heavy as the pilot rolled over into his dive, lining up red lines at 60°, 75° or 80° on the cockpit side window with the horizon and aiming at the target with the sight of the fixed gun. The heavy bomb was swung down clear of the propeller on crutches prior to release.

Diving procedure

Flying at 4,600 m (15,100 ft), the pilot located his target through a bomb sight window in the cockpit floor. The pilot moved the dive lever to the rear, limiting the "throw" of the control column. The dive brakes were activated automatically, the pilot set the trim tabs, retarded his throttle and closed the coolant flaps. The aircraft then rolled 180°, automatically nosing the aircraft into a dive. Red tabs protruded from the upper surfaces of the wing as a visual indicator to the pilot that, in case of a g-induced black-out, the automatic dive recovery system would be activated. The Stuka dived at a 60-90° angle, holding a constant speed of 500–600 km/h (350-370 mph) due to dive-brake deployment, which increased the accuracy of the Ju 87's aim.

When the aircraft was reasonably close to the target, a light on the contact altimeter came on to indicate the bomb-release point, usually at a minimum height of 450 m (1,480 ft). The pilot released the bomb and initiated the automatic pull-out mechanism by depressing a knob on the control column. An elongated U-shaped crutch located under the fuselage swung the bomb out of the way of the propeller, and the aircraft automatically began a 6 g pullout. Once the nose was above the horizon, dive brakes were retracted, the throttle was opened, and the propeller was set to climb. The pilot regained control and resumed normal flight. The coolant flaps had to be reopened quickly to prevent overheating. The automatic pull-out was not liked by all pilots. Helmut Mahlke later said that he and his unit disconnected the system because it allowed the enemy to predict the Ju 87s recovery pattern and height, making it easier for ground defences to hit an aircraft.

Physical stress on the crew was severe. Human beings subjected to more than 5 g forces in a seated position will suffer vision impairment in the form of a grey veil known to Stuka pilots as "seeing stars". They lose vision while remaining conscious; after five seconds, they black out. The Ju 87 pilots experienced the visual impairments most during "pull-up" from a dive.

Eric "Winkle" Brown RN, a British test pilot and Commanding Officer of Captured Enemy Aircraft Flight section, tested the Ju 87 at RAF Farnborough. He said of the Stuka, "I had flown a lot of dive-bombers and it’s the only one that you can dive truly vertically. Sometimes with the dive-bombers...maximum dive is usually in the order of 60 degrees.. When flying the Stuka, because it’s all automatic, you are really flying vertically... The Stuka was in a class of its own."

Once the Stuka became too vulnerable to fighter opposition on all fronts, work was done to develop a replacement. None of the dedicated close-support designs on the drawing board progressed far due to the impact of the war and technological difficulties. So the Luftwaffe settled on the Focke-Wulf Fw 190 fighter aircraft, with the Fw 190F becoming the ground-attack version. The Fw 190F started to replace the Ju 87 for day missions in 1943, but the Ju 87 continued to be used as a night nuisance-raider until the end of the war.

No comments:

Post a Comment